Margarine Plants

Price 2000 USD ($)/ Plant

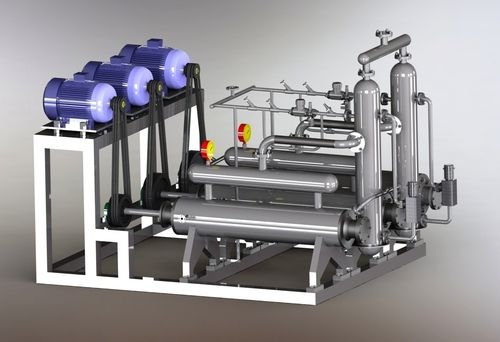

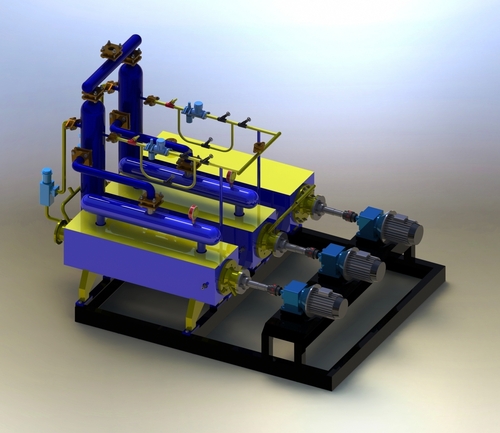

Margarine Plants Specification

- Accessories

- Standard, With Fittings

- Production Capacity

- As Per Requirement

- Installation Guideline

- Onsite Installation & Commissioning Support

- Efficiency (%)

- Above 90%

- Driven Type

- Electric

- Automation Grade

- Fully Automatic

- Motor Power

- 7.5 kW

- Frequency

- 50/60 Hz

- Temperature Range

- 5C to 60C

- Speed

- Variable

- Usage & Applications

- Margarine & Fat Processing, Food Industry

- Model No

- MG-2024

- Type

- Margarine Plant

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 380 V

- Power

- 14 kW

- Weight (kg)

- 6000

- Dimension (L*W*H)

- 8000 x 2600 x 2800 mm

- Color

- Silver

- Capacity

- 1000-10000 Kg/day

- Features

- Corrosion Resistant, High Efficiency, Easy Operation

- Surface Finish

- Polished

- Machine Type

- Continuous

- Power Consumption

- Low

- Processing Section

- Emulsification, Pasteurization, Cooling, Crystallization

- Safety System

- Overload Protection, Emergency Stop

- Design Life

- 15+ Years

- Cooling System

- Chilling Water & Ammonia

- Production Line Components

- Emulsifier, Scraped Surface Heat Exchangers, Resting Tubes, Filling & Packing Units

- Sanitation

- CIP (Clean-in-Place) Enabled

- Operator Interface

- Touch Screen HMI

- Oil Phase Temperature Control

- Automatic

- Water Phase Mixer Material

- SS 304/316

- Noise Level

- <= 80 dB

Margarine Plants Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 1 Plant Per Month

- Delivery Time

- 1 Months

About Margarine Plants

Commercial Applications & Directions for Margarine Plants

Margarine Plants like the MG-2024 are decorated solutions for mass food production, suitable for bakeries, confectioneries, and industrial kitchens. Their crackerjack performance ensures consistent output and quality in margarine & fat processing. Easy to use, operators simply follow the intuitive touch screen interface for seamless control, ensuring safe and efficient operations in commercial or manufacturing settings, large-scale food production centers, and export facilities.

Delivery, Market, and Payment Terms for Margarine Plants

With prompt transportation and trusted goods transport partnerships, delivery times are minimizedensuring your order reaches you quickly, whether in metro cities or remote locations. Serving the main domestic market across India, we prioritize customer convenience with lowest price guarantees and flexible payment terms. Our expert team provides onsite installation support and commissioning for hassle-free setup, making us your dependable exporter, manufacturer, and supplier.

FAQs of Margarine Plants:

Q: How is the margarine processed in the MG-2024 plant?

A: The process involves sophisticated emulsification, pasteurization, cooling, and crystallization. Each phase is computer-controlled for optimal output and quality, ensuring high efficiency and automation throughout production.Q: What are the key benefits of using this margarine processing plant?

A: Users benefit from high efficiency (above 90%), easy operation, corrosion-resistant materials, and advanced safety systems. The CIP-enabled design ensures sanitation, while the automated controls and competitive pricing make it highly cost-effective.Q: Where can this margarine plant be applied?

A: The MG-2024 margarine plant is ideal for commercial bakeries, confectionery manufacturers, large-scale food processing industries, and export-oriented facilities seeking reliable, continuous margarine and fat production.Q: When can customers expect delivery after reserving the plant?

A: Delivery times are optimized through strategic goods transport partnerships, ensuring quick and dependable shipments throughout India, with timely setup by our installation support team.Q: What capacity options are available for this plant?

A: The plant offers flexible production capacities, ranging from 1,000 to 10,000 kg per day, tailored to customer requirements to support diverse commercial or industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Margarine Plant Category

Table Margarine Plant

Price 2000 USD ($) / Plant

Minimum Order Quantity : 1 Plant

Computerized : Yes

Control System : Other, PLC Controlled

Automatic Grade : Automatic

SS Margarine Plant

Price 3200000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Human Machine Interface

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Margarine Plant

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Human Machine Interface

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Votator Machine

Price 1200000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Human Machine Interface

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Send Inquiry

Send Inquiry